Chris Fisher of Ducker Carlisle outlines how smart positioning and specialization will define winners

To begin, could you share details of your career history and how you came to be in your current position?

I’ve spent over 30 years in the global construction and industrial sectors, working both in consulting and on the operating side in corporate development for multinational corporations. Today, I lead Ducker Carlisle’s Global Building and Construction practice, where we help corporate executives and private equity firms grow, improve, and advance their businesses.

After two years of tightening conditions, your latest outlook suggests the US construction market is finding its floor. What signals are you seeing that indicate the downturn is nearing its end?

The most important signal is the Federal Reserve’s decision to cut its benchmark rate and signal the potential for further reductions in 2026. Combined with improving economic conditions, this will lift sentiment among builders and consumers. We’re also seeing steady investment and project planning in data centers and reindustrialized light manufacturing tied to Al growth and domestic trade policy. In addition, commercial occupancy levels and business cashflows are improving; two reliable indicators of future investment.

You forecast a housing rebound by early to mid-2026. What factors will drive that recovery, and how quickly do you expect builders to regain momentum once interest rates begin to ease?

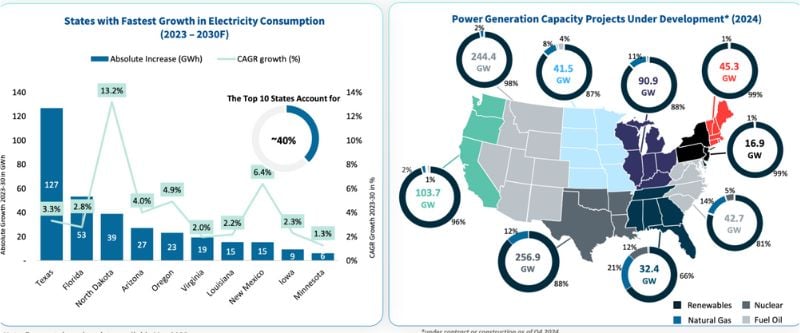

There’s pent-up demand among both move-up and first-time buyers waiting for mortgage rates to drop below six percent. Historically, it takes two or more quarters for rate cuts to translate into lower mortgage rates that stick. We anticipate further reductions ahead, which should drive renewed momentum in housing later in 2026. Southern states are expected to capture nearly half of all national construction spending by 2029.

What’s behind this regional strength, and how should contractors and suppliers be positioning themselves to take advantage?

The South continues to lead due to strong population growth, housing demand, and employment levels. Developers are drawn by available land, business-friendly tax policies, and a longer construction season. The best way to grow is to follow growth, contractors should be rebalancing geographic capabilities and positioning themselves where demand is strongest.

Nonresidential construction is showing resilience, particularly in data centers, healthcare, and lodging. What distinguishes these sectors from others in terms of growth potential and investment appeal?

Each sector has unique demand drivers. Data centers are fueled by Al and the race among tech firms to expand processing capacity at scale. Healthcare construction remains strong given its share of national GDP and the need for diverse facility types, from hospitals to outpatient centers. Lodging, while cyclical, is benefitting from rising consumer spending on travel and experiences, particularly among younger, experience-driven demographics.

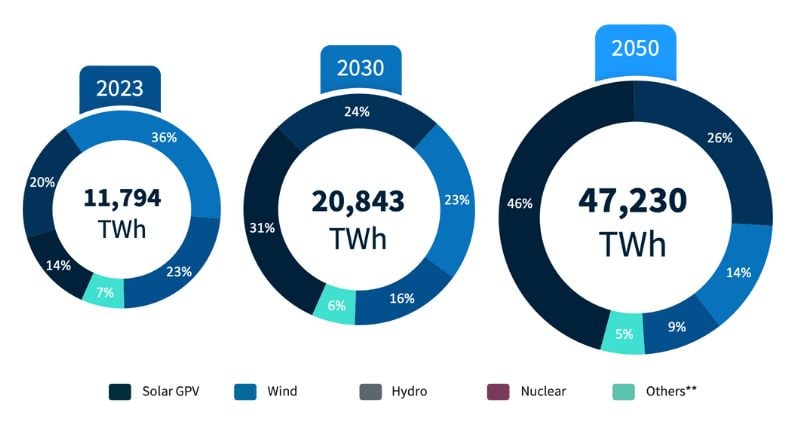

Data center construction alone is projected to exceed $50 billion by 2029. How is this surge reshaping demand for materials, labor, and project delivery models?

Data centers have highly specialized requirements; structural, thermal, and electrical that not every contractor can meet. We’re seeing firms create dedicated teams focused solely on data center projects, following investor demand nationwide. This specialization has tightened labor availability and extended lead times for traditional projects, opening new opportunities for contractors serving adjacent sectors.

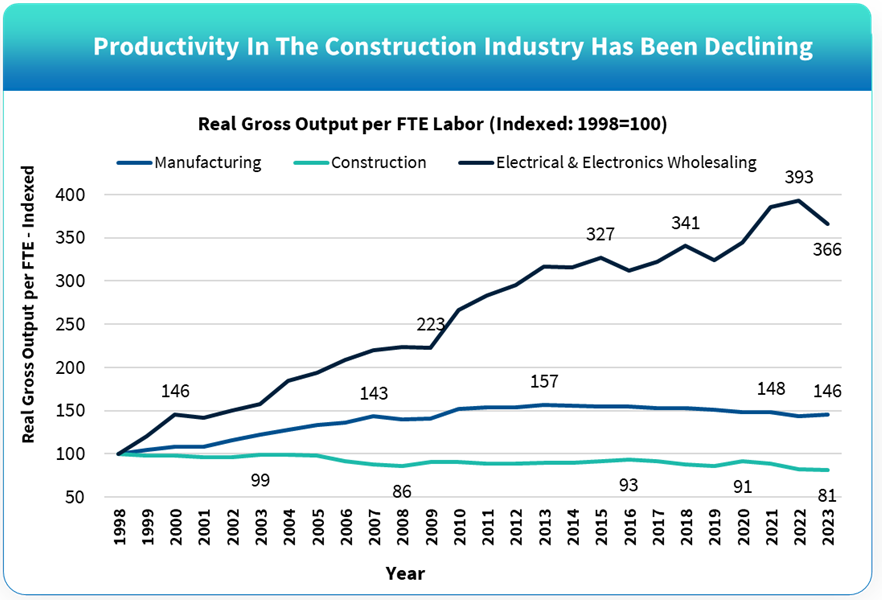

Labor shortages and cost inflation continue to pressure margins. How are contractors leveraging Al-driven bidding, off-site manufacturing, and other innovations to stay competitive?

Leading contractors are using Al to identify and bid on the right projects faster, manage labor allocation, and improve conversion rates. Many are also investing in off-site manufacturing and modular assembly to improve predictability and reduce labor intensity. Were seeing more collaboration and partnership models across project types and regions, as firms experiment with outsourcing and self-perform strategies. in trades like electrical, HVAC, and building envelope, some contractors are capturing more value through prefabrication, bundled services, and light fabrication.

When it comes to supply chain efficiency, what trends are you seeing around value-add distribution, and how might this change relationships between manufacturers, distributors, and contractors?

The professional contractor channel is being reshaped by well-capitalized players like Home Depot, Lowe’s, and OXO, who are using technology and scale to drive productivity and simplify procurement. At the same time, tariffs have shifted sourcing dynamics, creating opportunities for domestic manufacturers and distributors to take on more of the acquisition, assembly, and supply functions traditionally handled overseas.

As the market transitions from contraction to gradual growth, what risks should construction leaders keep top of mind?

Construction leaders should focus on disciplined execution and service quality, resisting the urge to overextend in pursuit of short-term gains, Growth without process and people readiness can undermine long-term performance, Clients have long memories, and firms that consistently deliver quality, meet deadlines, and communicate effectively are the ones that secure repeat business.

How is investor sentiment evolving around the construction and building products sector, and what does that mean for M&A activity or capital investment over the next few years?

Investor interest is strong. Private equity is now focused on contractor service platforms after years of consolidation in distribution. The sector benefits from multiple growth drivers-underbuilt housing, reindustrialization, and long-term infrastructure spending. These fundamentals make construction one of the more attractive segments for capital investment over the next cycle.

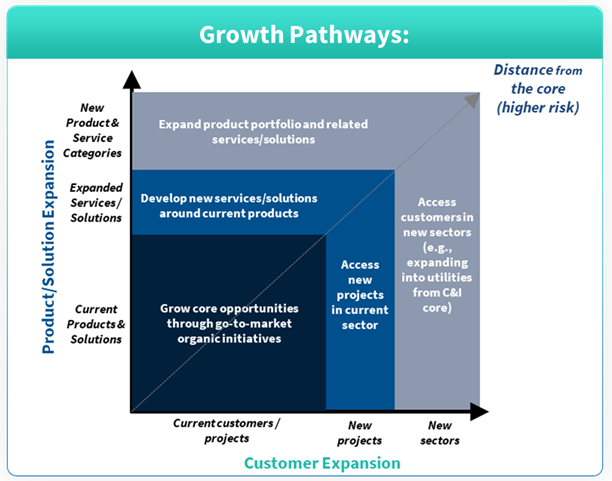

Looking toward 2029, what defines success for the construction firms that emerge strongest from this cycle

Like past cycles, we typically see the high performers have invested and optimized their business to build advantage or strong competencies which include:

- – Sticky customer relationships and strong customer value propositions

- – Consistent execution and quality of offering or experience – reliability and consistency are key

- – Demonstrated capabilities to form partnerships and innovate across investment, design, supply and installation.

- – A business doesn’t have to own or control all aspects to form valuable, committed partnerships

- – Al and technology enabled execution will be particularly important

- – Ability to pursue and adjust business mix across regions, project types, product segments and value chains.

Agility and collaboration will define the next generation of construction leaders.

Source URL : https://magazine.construction-today.com/construction-today-vol-22-issue-6/0565720001764588820